Automotive

When Talent Gaps Disrupt Throughput and Quality

Automotive organisations operate within tightly coupled systems where quality, safety and delivery timelines are non-negotiable. Experienced professionals anchor production stability, supplier readiness and process discipline. When critical roles remain vacant or underpowered, the impact cascades quickly across lines, vendors and customers.

Delays, quality escapes and rework are rarely isolated issues. They are symptoms of capability gaps within engineering, manufacturing and quality functions. Automotive leaders increasingly recognise that hiring decisions directly influence throughput reliability and long-term competitiveness.

Core Automotive Capability Areas

Automotive performance depends on a set of interdependent capability areas. Each area requires depth of experience, process maturity and operational judgment.

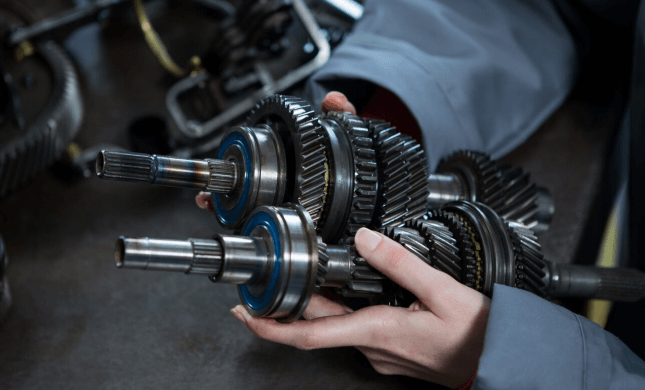

Product and Manufacturing Engineering

This capability ensures designs translate reliably into manufacturable products. Strong teams here reduce late-stage changes and stabilise production. Key focus areas include product engineering, process engineering, tooling readiness and manufacturability optimisation.

Production and Operations

Operations capability determines daily output, line stability and adherence to safety standards. Teams here manage line balancing, capacity planning, shift discipline and continuous improvement across plants.

Quality and Compliance

Quality capability protects brand trust and regulatory alignment across products and suppliers. This includes incoming quality, in-process controls, audit readiness and corrective action management.

Supply Chain and Vendor Management

Supplier capability directly influences production continuity. Teams manage supplier quality, readiness, logistics coordination and risk mitigation across tiers.

Program and Industrialisation Management

Program capability ensures new models and variants transition smoothly from concept to production. This includes launch planning, cross-functional coordination and milestone governance.

Why Automotive Talent Has Become a Strategic Constraint

Automotive organisations are operating under structural shifts that have permanently raised the bar for talent quality. Experience gaps now surface faster and carry higher operational cost.

What is changing

- Electrification and new powertrain technologies increasing complexity

- Tighter regulatory and safety expectations

- Higher localisation and supplier dependency

- Compressed launch timelines

What leaders are experiencing

- Greater reliance on seasoned professionals for decision-making

- Limited availability of talent with real plant and supplier exposure

- Increased competition for operational and quality leaders

Talent availability now directly influences throughput stability, launch confidence and long-term operational maturity.

Technical Roles That Shape Delivery Outcomes

We focus on high impact roles that determine how well teams execute.

Production Engineer

Quality Engineer

Frontend Engineer

Experience: 2 to 5 years.

Senior Manufacturing Engineer

Experience: 7 to 12 years.

Supplier Quality Manager

Experience: 8 to 14 years.

Senior Platform Engineer

Plant Operations Head

Experience: 15+ years.

Director of Manufacturing Excellence

Experience: 15+ years.

Senior Platform Engineer

A Hiring Process Built for Operational Judgment

Automotive hiring requires more than technical credentials. It demands evidence of decision-making under real production constraints.

Leadership alignment on operational outcomes

Role definitions anchored in plant and program realities

Scenario-based discussions drawn from production, quality and supplier situations

Assessment of safety, compliance and escalation judgment

What Leaders Gain From Capability-Aligned Hiring

When hiring aligns to operational capability, leaders see measurable improvement.

Observed Outcomes

- Improved line stability and throughput predictability

- Reduction in quality escapes and rework

- Smoother new product introductions

- Stronger supplier discipline and readiness

Why Leaders Choose Adept

- Clear understanding of plant realities

- Access to seasoned automotive professionals

- Structured evaluation grounded in real scenarios

- Predictable communication and delivery

Trusted by these amazing companies

Testimonials

Adept helped us stabilise production by placing engineers who understood plant realities, not just design theory.

Suresh Patel

Plant Head, Automotive OEM

The candidates brought practical judgment that immediately improved audit outcomes and supplier discipline.

Neha Kulkarni

Head of Quality, Tier 1 Supplier

Our hiring outcomes improved noticeably once we aligned roles with operational capability.